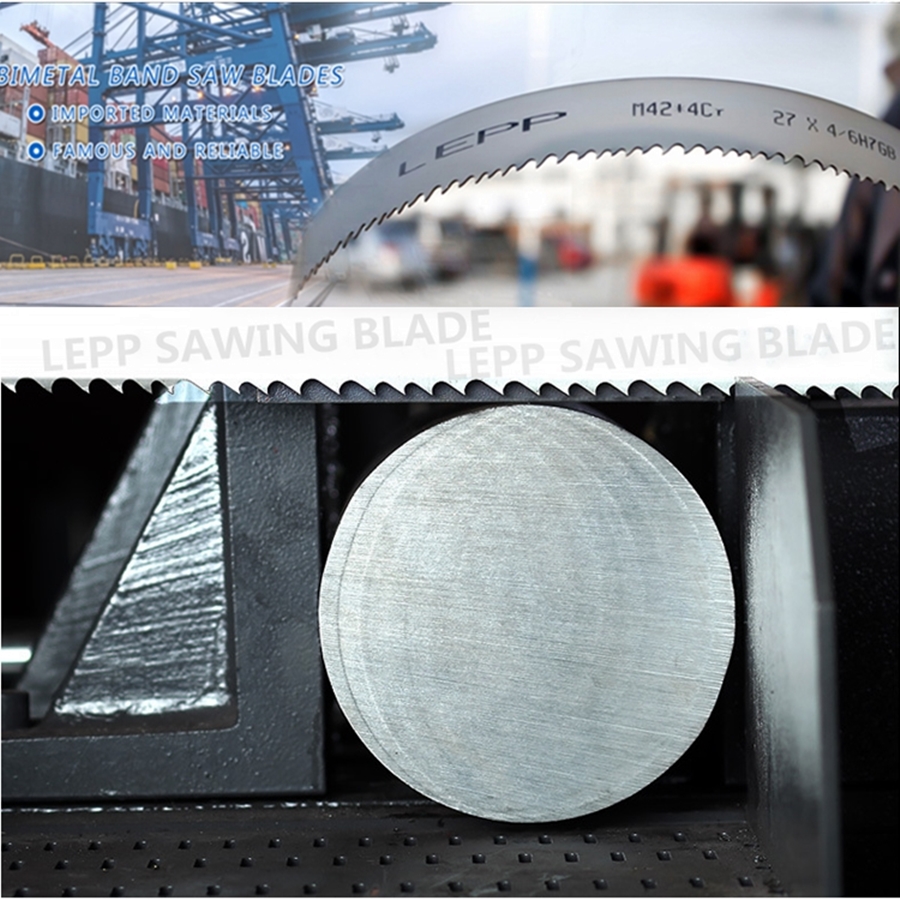

I-Bi Metal Band Saw Blade

Imininingwane

| UmkhiqizoIgama | I-Professional Hss Bi-metal Band Saw Blade Yomshini Wokulola I-blade |

| Okubalulekile | i-M51/M42 |

| Ukucaciswa | 27mm*0.9 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 8/12TPI 10/14TPI 34mm*1.1 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 8/12TPI 10/14TPI 41mm*1.3 1.4/2TPI 1/1.5TPI 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 8/12TPI 54mm*1.6 0.75/1.25T 1.4/2T 1/1.5T 2/3TPI 3/4TPI 4/6TPI 5/8TPI 6/10TPI 67mm*1.6 0.75/1.25T 1.4/2T 1/1.5T 2/3TPI 3/4TPI 4/6TPI 5/8TPI 80mm*1.6 0.75/1.25T 1.4/2T 1/1.5T 2/3TPI |

| Okubalulekile Ukusika | carbon steel/isikhunta steel/Ingxubevange steel/Stainless steel |

| Izinzuzo | Izinto ezisetshenziswayo ezifaka i-m42 bi-metal bandsaw blade iyisakhiwo sensimbi esiphindwe kabili: i-B318 isekela, amandla okukhathala; M42 impahla yezinyo, 8% okuqukethwe kwe-cobalt, ubulukhuni bezinyo HRC67-69Inzuzo enkulu ye-bi-metal band saw blade yile: 1. Ukumelana nokugqoka okuphezulu nokuqina okubomvu okuphezulu; 2.I-Serrated akulula ukuyiphula; 3. Impilo ende yesevisi. |

| Amaphakheji | ama-blade anesembozo sepulasitiki bese kuba ama-pcs ayi-10 ebhokisini/ibhokisi elilodwa |

| I-oda elincane | Nezidingo zamakhasimende |

| Ukulethwaisikhathi | Izinsuku ezingu-7 ngemva kwenkokhelo ethuthukisiwe |

I-Bimetal Band Saw Blade

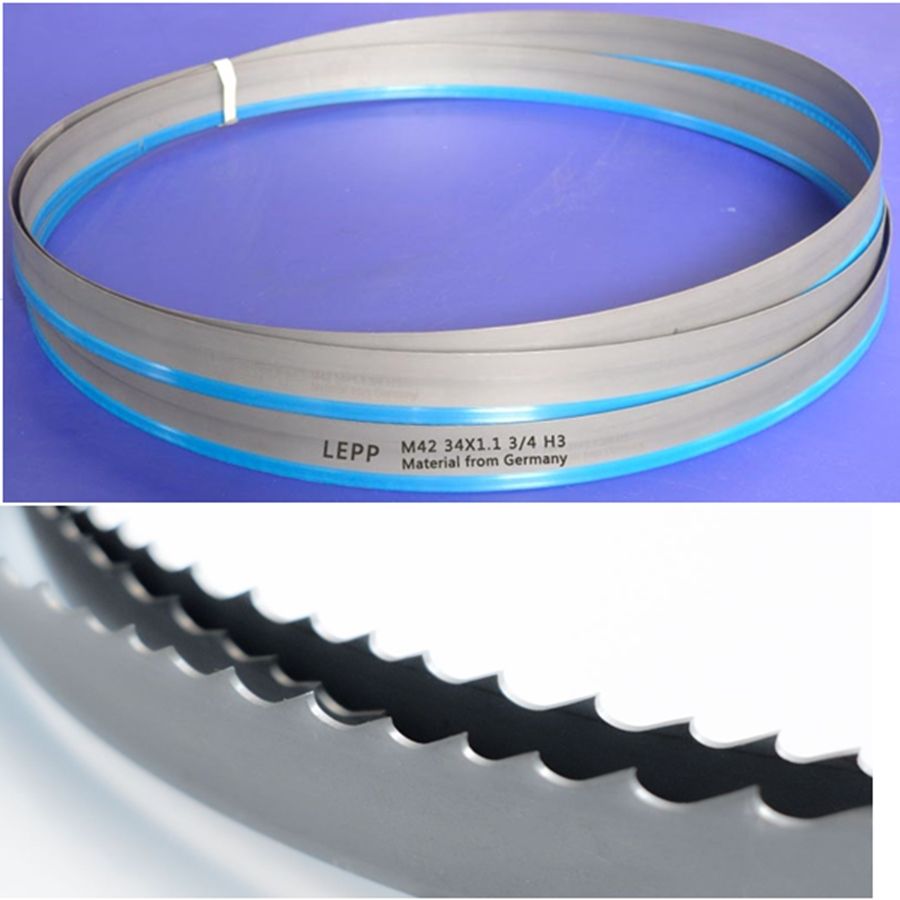

I-M42 Bimetal Band Saw Blade ene-Cobalt

Le bhendi yamasaha esebenza kahle kakhulu ifaneleka ngokukhethekile ukusikwa kwe-serial kwazo zonke izinhlobo zezinsimbi. Amazinyo enziwe ngensimbi enejubane eliphezulu engu-8% ne-cobalt engu-10% ye-molybdenum.

Izinzuzo:

★ 30-100% ukwanda isivinini ukusika uma kuqhathaniswa ithuluzi steel band saw izindwani

★ kuze kufike ku-50% ukunciphisa isikhathi sokusika, okuholela ekukhiqizeni okuphezulu.

★ Impilo yokusebenza izikhathi ezingu-10 kunezinsimbi zensimbi zensimbi zanda ukunemba kokusika

★ Lezi zinzuzo ziholela ekusebenzeni okungabizi kakhulu kokusika kokubili kwezicelo zesikhathi esisodwa kanye nokukhiqizwa kwe-serial.

I-M51 Bimetal Band Saw Blade ene-Cobalt ne-Tungsten

Le blade ye-saha ye-band yakhelwe ukusetshenziswa ezinhlelweni zokusika ezisindayo. Ukusebenza kokusika kwamazinyo ensimbi ngesivinini esikhulu kwanda kakhulu ngokusebenzisa i-alloying ne-cobalt tungsten. Lezi zakhi ze-alloying zandisa kakhulu ukumelana nokushisa kanye nokumelana nokukhathala.

Izinzuzo:

★ isikhathi eside sokusebenza.

★ ukwanda ukunemba ukusika.

Ivumela ukusikwa okuyongayo kwezinto ezinokugcinwa okuphansi njengensimbi engagqwali.

Imininingwane Yomkhiqizo

Amaphuzu okusebenza komshini wokusaha (gcina kahle impilo yesevisi yama-saw blades, ukulungiswa komshini wokusaha kubaluleke kakhulu):

1. Ingalo yomhlahlandlela:

Ukulungisa ingalo eqondisayo eduze ngangokunokwenzeka kokuqukethwe.

2. Isondo lomhlahlandlela:

Hlola ukuthwala ukuze uthole ukugqokwa nokulimala, ngale ndlela isondo eliqondisayo lingaqondisa ngempumelelo isaha.

3. Isondo lensimbi yensimbi:

Hlola ukuma kwesondo lensimbi yensimbi ukuze uqinisekise ukuthi i-chip ingasuswa ngempumelelo.